Feedback & RecreateAdd image manually

Feedback & RecreateAdd image manually

For professional refiners, identifying and processing high-yield electronic scrap is the key to profitability. Integrated circuits, or IC chips, represent one of the most concentrated sources of gold within e-waste. This guide provides a direct, no-nonsense overview for businesses looking to identify, value, and process IC chip scrap to maximize gold recovery. Learn how to distinguish valuable components and secure a reliable bulk supply for your operations.

What is IC Chip Scrap and Why is it Valuable for Gold Recovery?

In the context of e-scrap, an Integrated Circuit (IC) chip is a semiconductor device that performs electronic functions. Their value to refiners comes from a critical component: microscopic gold bonding wires. These wires, thinner than a human hair, are used to connect the silicon die to the chip’s external pins. Because of this construction, IC chips are a far more concentrated source of gold than other e-scrap components like gold-plated fingers or pins, making them a prime target for recovery operations.

Key Types of IC Chips for Precious Metal Refining

- Plastic ICs (Epoxy): These are the most common type of chip found in modern electronics. They are typically black and rectangular. While they do contain gold, their yields are lower and can be highly variable depending on the chip’s age and function.

- Ceramic ICs: Often found in older computing, server, and military equipment, ceramic ICs are highly sought after. Their ceramic bodies (which can be purple, brown, white, or gray) typically house components with a higher and more consistent gold content.

- Ball Grid Array (BGA) Chips: These are modern, high-density chips common in laptops, mobile phones, and networking equipment. They have a grid of solder balls on their underside and can contain valuable amounts of gold, often in the form of fine powder within their structure.

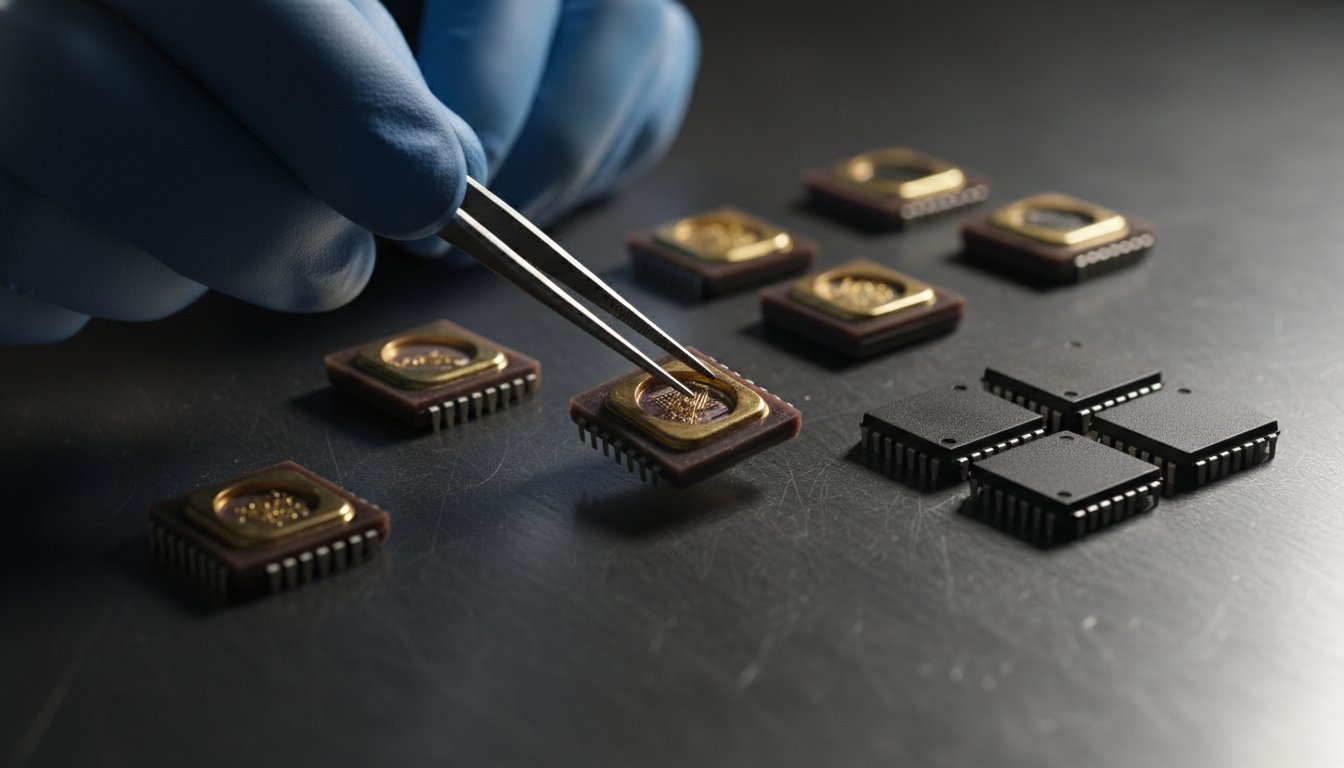

Visual Inspection: How to Identify High-Yield IC Chips

Quickly identifying potentially valuable chips is a crucial skill. While a full assay is the only way to confirm value, certain visual cues can help you sort material effectively. Focus on older, heavier components from high-performance equipment. The table below outlines key indicators.

| Visual Cue | Potential Value Indicator |

|---|---|

| Ceramic Body (Purple, Brown, White) | High – Often indicates older manufacturing with higher gold content. |

| Gold Lid or Heat Spreader | High – The visible gold plating is a strong sign of value. |

| Chips from Server or Military Equipment | High – These were built for reliability, often using more gold. |

| Older, Larger Plastic Chips (pre-2000) | Medium – Can contain more gold than modern, smaller equivalents. |

| Small, Modern Plastic Chips | Low to Medium – Yields are generally lower and more variable. |

Estimating Gold Yields and Value from IC Chip Scrap

For professional refining operations, understanding potential yield is critical for calculating ROI. Gold yields from IC chips are typically measured in pounds per ton or grams per kilogram. It is essential to recognize that these yields vary widely based on the specific mix of chips being processed. An assorted lot of modern plastic ICs will have a vastly different return than a sorted batch of vintage ceramic server CPUs.

Factors That Influence Gold Content

- Manufacturing Era: As a general rule, chips manufactured before the year 2000 often contain significantly more gold. Cost-saving measures in later decades led to reduced precious metal usage.

- Chip Function: High-performance components like CPUs, memory controllers, and specialized processors from servers or mainframes typically have higher gold content than common, low-power chips.

- Manufacturer Specifications: Components built for military, aerospace, or high-reliability enterprise applications were often manufactured with higher gold content to ensure longevity and performance under stress.

Average Yield Expectations (By Chip Type)

While exact figures require a chemical assay, industry experience provides general expectations. Note that these are estimates and can vary.

- Ceramic ICs: These are the highest-grade chips and can yield significant amounts of gold. Yields can be substantial, making them a top-tier recovery material. (Note: Verify specific yield data from industry sources before purchase).

- Plastic ICs: The gold yield from plastic ICs is much lower and more inconsistent. Processing them requires handling large volumes to achieve a profitable return. (Note: Verify specific yield data from industry sources before purchase).

- BGA Chips: The value in BGA chips often comes from the fine gold powder recovered after incineration and milling. The yield depends on the specific chip but can be worthwhile for specialized processors.

Sourcing Bulk IC Chip Scrap for Maximum Profit

The primary challenge for any refiner is securing a consistent supply of high-quality, well-sorted material. While buying unprocessed circuit boards is an option, it involves significant labor in depopulation and sorting. A more efficient approach is to buy sorted IC chips in bulk. This strategy offers a higher concentration of value per kilogram and dramatically reduces your in-house pre-processing labor and costs. At Ceramic Gold Scrap, we provide clean, sorted IC chip scrap that is ready for your refining operation, allowing you to focus on what you do best: recovering precious metals. For a reliable supply of high-yield material, View Our Bulk IC Chip Scrap for Sale.Feedback & RecreateDelete

Essential Processing Steps for Gold Recovery from ICs

Disclaimer: The following information is for educational purposes only. Gold recovery involves the use of hazardous chemicals and should only be performed by trained professionals in a controlled, properly ventilated environment with appropriate personal protective equipment (PPE). The objective of chemical processing is to efficiently separate the gold from the surrounding ceramic, plastic, and base metals like copper and aluminum.

Step 1: Depopulation and Preparation

- Removal: Chips must first be removed, or “depopulated,” from the circuit boards. This is often done using a heat gun to melt the solder joints, allowing the chips to be carefully pried off.

- Sorting: For predictable results, it is crucial to sort the removed chips by type (e.g., ceramic, plastic, BGA) before beginning any chemical process.

- Crushing: To maximize the effectiveness of chemical reactions, chips are often crushed or milled into a fine powder. This greatly increases the surface area exposed to the chemicals.

Step 2: Chemical Leaching and Precipitation

- Chemical Methods: Common professional methods involve using powerful acids like Nitric Acid or a mixture known as Aqua Regia (nitric acid and hydrochloric acid) to dissolve the other metals.

- Purpose of Leaching: The goal of this step is to dissolve all the base metals (copper, iron, tin, etc.) that make up the chip’s pins and internal structure, leaving the inert gold and ceramic/plastic material behind.

- Precipitation: After the gold is dissolved (in the case of Aqua Regia), a precipitant is added to the solution. This chemical causes the gold to “drop out” of the solution as a fine brown powder, which can then be collected, washed, and melted into a button.

Frequently Asked Questions

How much gold is in 1 kg of IC chip scrap?

This amount varies dramatically. 1 kg of high-grade ceramic ICs could contain several grams of gold, whereas 1 kg of low-grade mixed plastic ICs might contain less than a gram. Value is determined by the quality and type of chips, not just the weight.

Are all black plastic IC chips worth scrapping?

Not always. While most contain some gold, the amount in small, modern plastic chips can be so minimal that the cost of processing exceeds the value of the recovered gold. It is often more profitable to focus on larger, older plastic chips or higher-value ceramic types.

Is it more profitable to sell whole boards or depopulated IC chips?

Selling depopulated, sorted IC chips typically yields a higher price per kilogram because the buyer is getting a more concentrated, valuable product and does not have to perform the labor-intensive removal process themselves.

What is the difference between ceramic and plastic IC scrap value?

Ceramic IC scrap is significantly more valuable than plastic IC scrap on a per-pound basis due to its consistently higher gold content. Ceramic chips were often used in older, high-end applications where performance was prioritized over cost.

Can you recover other precious metals from IC chips?

While gold is the primary target, some IC chips, particularly certain types of capacitors and specialized chips, can also contain small amounts of silver and palladium (PGMs). However, gold is the main driver of value for most IC scrap.

Maximizing your returns from e-waste refining requires a focus on high-quality, well-sorted input materials. By understanding how to identify valuable IC chips and partnering with a reliable bulk supplier, you can streamline your operations and improve your bottom line. Ready to secure a consistent supply of high-yield material for your business? Shop Bulk IC Chip Scrap Now and get the quality feedstock your operation deserves.